Mutiara Indo Resources

Charcoal need Solution

Background

PT Mutiara Indo Resources is one of the company private national company engaged in the charcoal industry which was established in July 2019 ( see NIB : 9120105792827).

Our main uses are Steam Activated Carbon, Wood Charcoal and Coconut Shell Charcoal For various industry . We always offer the best for our customers . Based on the experience we have gained during for years , we are sure can give results the best you could hope for with uphold tall the values we believe in .

Have Steam Activated Carbon ability adsorption height used in various sector , starting from water treatment up to industry pharmacy . Understanding types and applications can help industry choosing the right activated carbon For increase efficiency production and quality product . And it is also a material that has porosity height and power absorb outside usual , so Lots used in various sector industry .

Steam Activated Carbon is a material based on processed carbon in a way special For own wide surface and power absorb height . Structure the pores allows this material absorb substance chemicals , odors , and particles dangerous from fluid and gas. And also often used in mesh or powder depending on needs application industry .

Can get Wood Charcoal and Coconut Shell Charcoal used as material standard for activated carbon , water filters, water purifiers .

Benefits of Steam Activated Carbon in industry :

Water and Waste Filtration . Eliminates substance organic and metal heavy from waste water industry . Used in water filter system for increase drinking water quality .

Use of Activated Carbon in the Gold Extraction Industry : With ability extraordinary adsorption normal , carbon active help absorb particle gold from solution .

Oil and Gas Industry . Separating compound dangerous from exhaust gases and products oil Earth . Used in the process of refining product oil and natural gas .

Air and Gas Treatment . Absorbs toxic gases and pollutants in industry chemistry . Used in gas masks and equipment purification air .

Pharmaceutical and Food Industry . Used in purification medicine and materials chemistry . Absorb substance color and smell in the production process food and Drink .

Vision and Mission

Vision

Become company leading , superior and competitive in import export manufacturing charcoal and Steam Activated Carbon.

Mission

1.Develop ability source Power man in a way sustainable .

2.Prioritize interests and satisfaction through service and quality best is key our main in to build and foster good cooperation .

3.Guard confidentiality information customer , buyer , or relation whatever .

4.Apply System Supportive Quality Management development company in a way overall For create activity effective and efficient operations .

5.Produce Bio Energy products that are quality , safe and environmentally friendly environment .

Build connection term interconnected length profitable with stakeholders interest .

Catalog Product

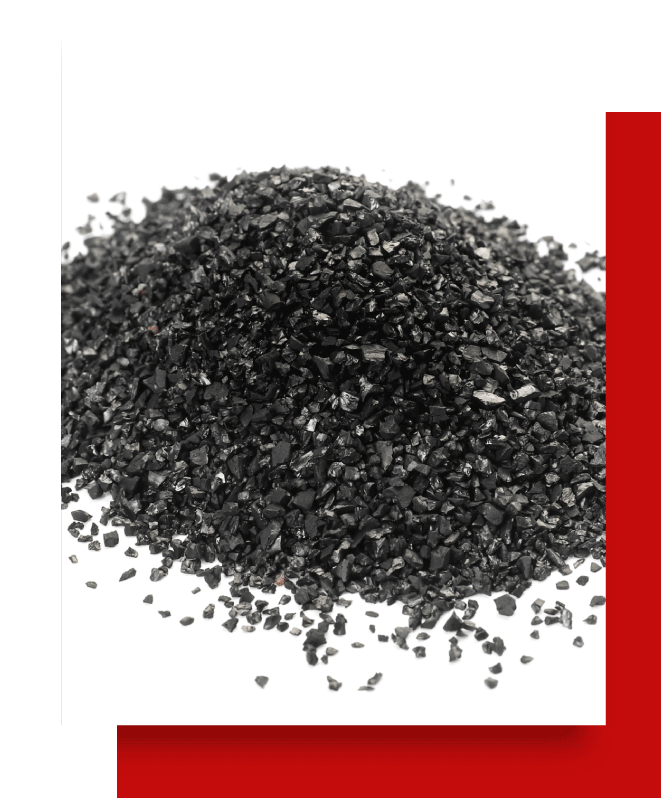

Steam Activated Carbon

Powder

Mesh

| Humidity | : 5% – 10% |

| Ash Content | : 3% – 10% |

| Absorption Value Iodine | : 800mg/G – 1200mg/G |

| Absorption Methylene Blue | : 150mg/G – 225mg/G |

| Contents Fervic | : ≤ 0.1% |

| Ph value | : 4 – 11 |

| Packaging | : Woven Bag 25 Kg/Pp & Jumbo Bag/Jumbo Bag 500 Kg/Pp |

| Production | : 2000 Kg/Day |

| Main Markets | : Asia (Malaysia, China, Korea, Japan ), Europe and Middle East |

| Use | : Water Filter, Helps Absorb Gold Particles From Solution , Assists in the Purification Process Product Oil and Gas Nature, Air Purification , Purification of Medicines and Materials Chemistry. |

Steam Activated Carbon Packaging

Jumbo Bag

Woven Bag

| Hardwood Charcoal | |

| Charcoal Size | : 5 cm – 10 cm |

| Humidity | : Maximum 12% |

| Ash & Powder | : Maximum 2% |

| Fixed Carbon | : Minimum 68% |

| Packaging | : 25 – 30 Kg / Pp Bag |

| Production | : 5,000 Kg / Day |

| Main Markets | : Europe , Middle East and Asia |

| Use | : Raw materials for activated carbon , water filters, water purifiers. |

| Coconut Shell Charcoal | |

| Charcoal Size | : 5 cm – 9 cm |

| Humidity | : Maximum 15% |

| Ash & Powder | : Maximum 2% |

| Fixed Carbon | : Minimum 70% |

| Packaging | : 25 – 30 Kg / Pp Bag |

| Production | : 5,000 Kg / Day |

| Main Markets | : Europe , Middle East and Asia |

| Use | : Raw materials for activated carbon , water filters, water purifiers. |

Process Flow Chart of Steam Activated Carbon Production

| NO | Picture | Description |

| 1 | | Incoming Material Control Activities The incoming raw materials will be weighed first to determine the weight, then random sampling of 1/2 kg is carried out on the front, middle and rear of the Fuso and after that testing or tests are carried out such as water content and ash content tests to determine whether the quality is appropriate or not. |

| | ||

| | ||

| 2 | | Screening and Sizing to 2.5 cmDrying Process The raw materials are sorted by being put into a sieving machine to separate the 1-2.5 cm charcoal which is temporarily stored as raw material for steam activated carbon and the 5 cm charcoal will be stored separately in a storage warehouse for charcoal. |

| | ||

| 3 | | Carbon Activation in Rotary Kiln Good quality raw materials will be fed into the rotary kiln machine, this activation process is carried out at a temperature ranging from 800˚C – 950˚C according to the production temperature standard and is carried out for 6 – 8 hours. The process of entering raw materials does not stop for 24 hours, raw materials in a day enter the rotary kiln machine as much as 3.5 to 3.8 tons producing approximately 2 tons of product results. The shrinkage that occurs in raw materials into finished products can be influenced by temperature, the rotation speed of the rotary kiln machine itself or the material Flow speed is around 3.5 minutes to 4.5 minutes of rotation which is set according to the desired quality. In this activation process, it is also assisted by steam 1,2,3 to be channeled into the rotary kiln machine and chimney which is useful for a place to dispose of excess temperature. |

| | ||

| | ||

| | ||

| 4 | | Cooling and Weathering After being removed from the rotary kiln, the steam-activated carbon products are placed in open drums, unpacked, and exposed to the open air, and under the roof. This process, known as the cooling and weathering process, takes a minimum of 14 days before final packing/being packaged. |

| | ||

| | ||

| 5 | | Final Inspection and Testing Quality Analysis Parameters: |

| | ||

| | ||

| | ||

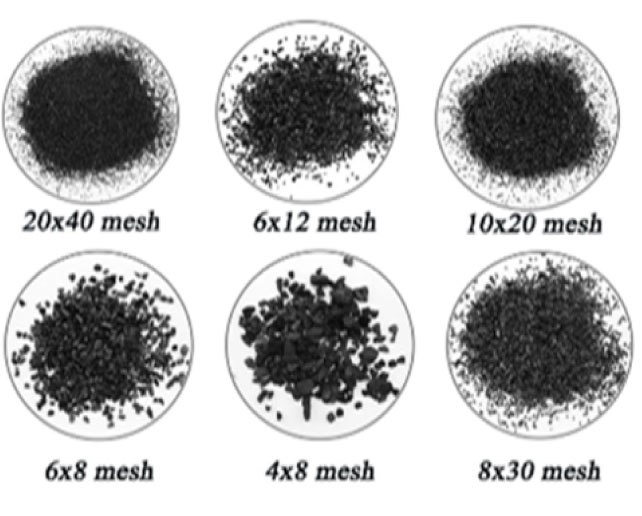

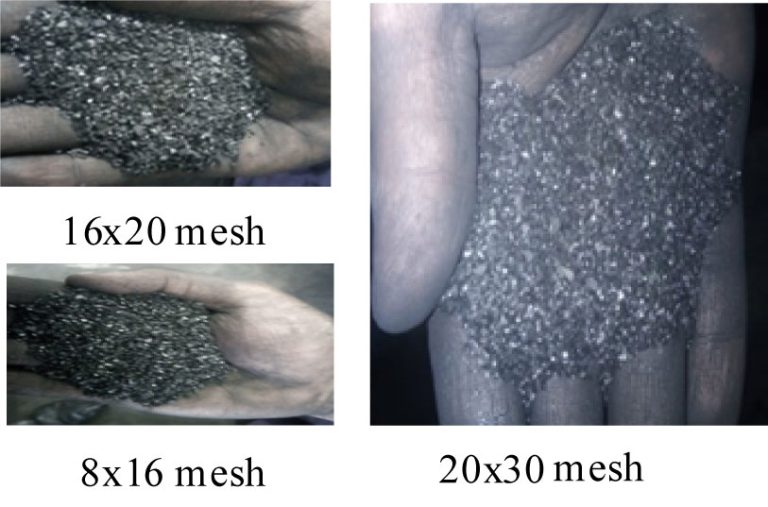

| 6 | | Crushing/Grinding Process Product Specifications: the steam activated carbon is available in granular form with the following mesh size options 20×40 Mesh, 6×12 Mesh, 10×20 Mesh, 6×8 Mesh, 4×8 Mesh and 8×30 Mesh. |

| 7 | | Packing and Storage The ordered packaging includes PP woven bags with inner plastic liners, each with a capacity of 25 kg, and Jumbo bags with a capacity of 500 kg. |

| | ||

| | ||

| |

Coconut Shell Charcoal Production Process

- Raw material

- Sort the raw materials and clean off excess coconut fiber.

- Put only some of the coconut shells in the burning drum.

- Light the fire from the bottom of the drum

- The combustion process

- The coconut shell will shrink and be refilled until the drum is full.

- When it is full, the smoke begins to disappear and only embers remain, cover the drum with a wet burlap sack and then sprinkle it with water. Cover the drum with its lid for 24 hours.

- The process of removing the combustion results from the drum to be dried, cooled and sorted first (minimum 14 days / depending on the weather)

- Enter the storage warehouse

- Second sort / quality control

- Drying / flatbed dryer and re-packing to ensure goods are in accordance with buyer requests by prioritizing the FIFO (First In First Out) system

- Check the quality with the provisions (KA 15% max, Dust 3% max, Size 0.5cm up VM 15% max)

- Packing and sewing sacks (40kg)

- Enter the storage warehouse for goods ready for export

Article

About Education About Charcoal and Activated Carbon

Coconut shell charcoal is not just an ordinary fuel. This material has many uses, ranging from the food industry, water filtration, to health. No wonder its demand continues to increase, both domestically and in the export market. Read More

Activated carbon may sound technical, but it is actually all around us and used in various daily applications. From drinking water filters and health masks to the pharmaceutical industry—activated carbon from wood charcoal is the top solution for filtration. Read More